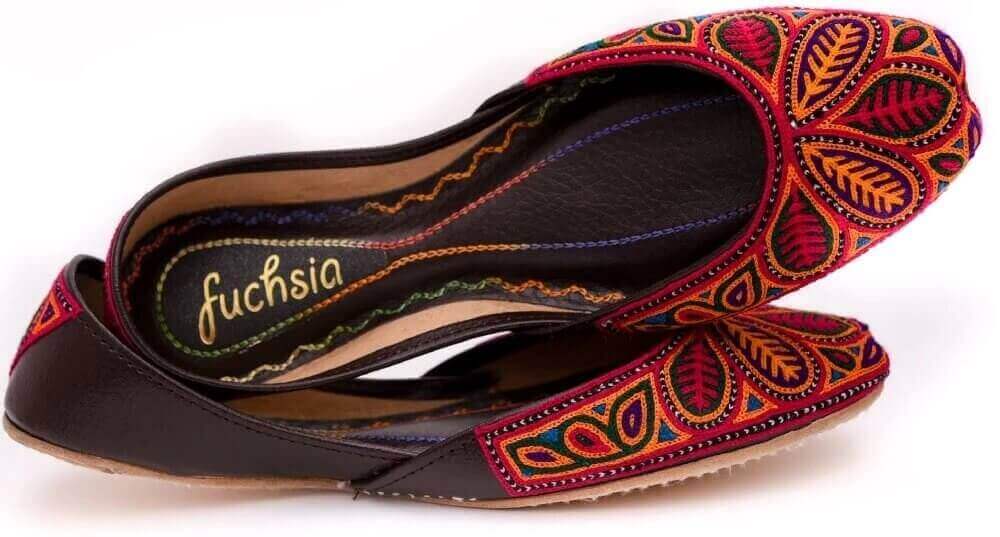

What!! It takes more than 30 steps to prepare Fuchsia Flats (Khusas, کھسہ).

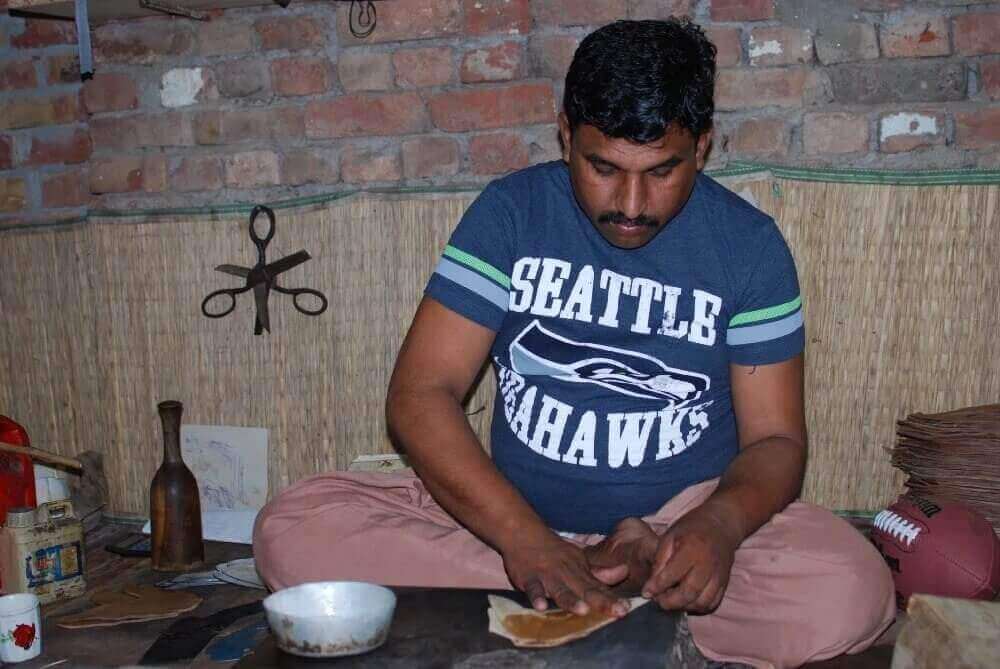

That was my initial reaction when I was told by my artisans. So I decided to spend a week with them in their factory and see it myself how Fuchsia Shoes are made.

Our artisans usually work on a batch of 40 to 60 pairs in one cycle and it takes them around a week (sometimes 2 weeks) to complete a cycle. The usually follow assembly line for their manufacturing. Some steps take from hours to days depending on weather and climate. Since a lot of people were interested in learning about the overall manufacturing process, I have listed down all the major steps of manufacturing process. We have made a condensed video of all these steps here.

- Acquire leather from tanneries.

2. Wash it with water, and let it dry. In summer it takes about 2 hours but in winter it can be up to 3 days.

3. Bring it to factory.

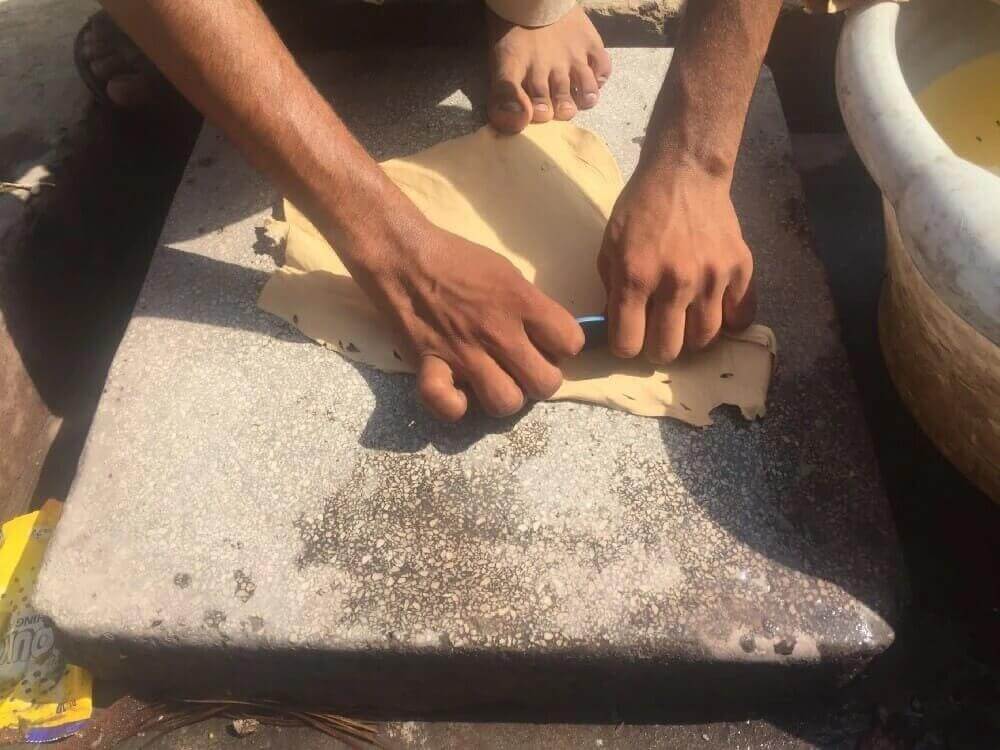

4. Out line the sizing with lead pencil.

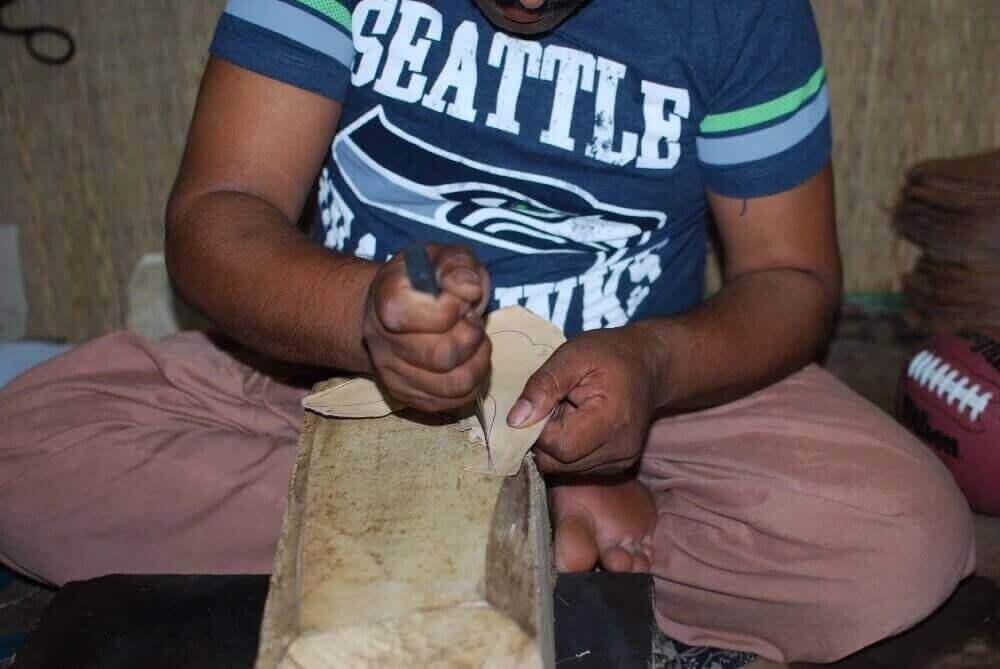

5. Cut it with one side cutter called Rumbi.

6. Make the gauge of the leather thin using a peeler.

7. Put tartar in water and let the leather soak in it. Now wash the leather to remove any spot or stains.

8. Apply tool (they call it ‘Guti’, yes it seems like some gaming character name :) to make it thin and get water and dirt out.

9. Put it outdoor to let it dry. In winter it takes up to 2 to 3 days in order for the leather to dry completely.

10. Apply the same tool again to give leather shine.

11. Lining with ball point and make it prominent.

12. Cutting the leather, following the outlines.

13. Apply solution to the cutting and let the solution dry.

14a . Embroidery is done in parallel. The embroidery artisans work in isolation. A single artisan cannot make more then 8 pairs per day (depending on the details of the embroidery)

14 b. Paste embroidery upper on leather.

15. Cut the edges with scissor.

16. Fold the inner suede and apply solution to edges.

17. Now come another fun part which is ‘Shoe stitching’. A typical artisan stitch between 10 to 15 shoes per day.

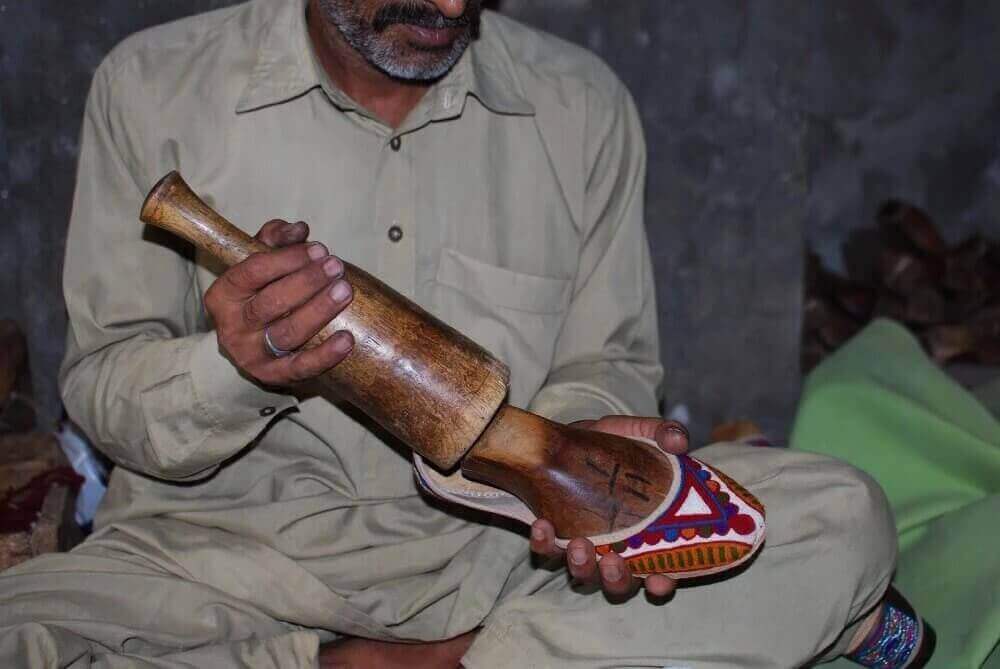

18. Apply shoe tree for sizing.

19. Clean the edges.

20. Take shoes out from shoe tree and apply tools to make the edges smooth and bring some shine on edges.

21. Apply solution to insole.

22. Paste inner sole and cover it.

23. Fuchsia Shoes are ready to be packed in a box.